-40%

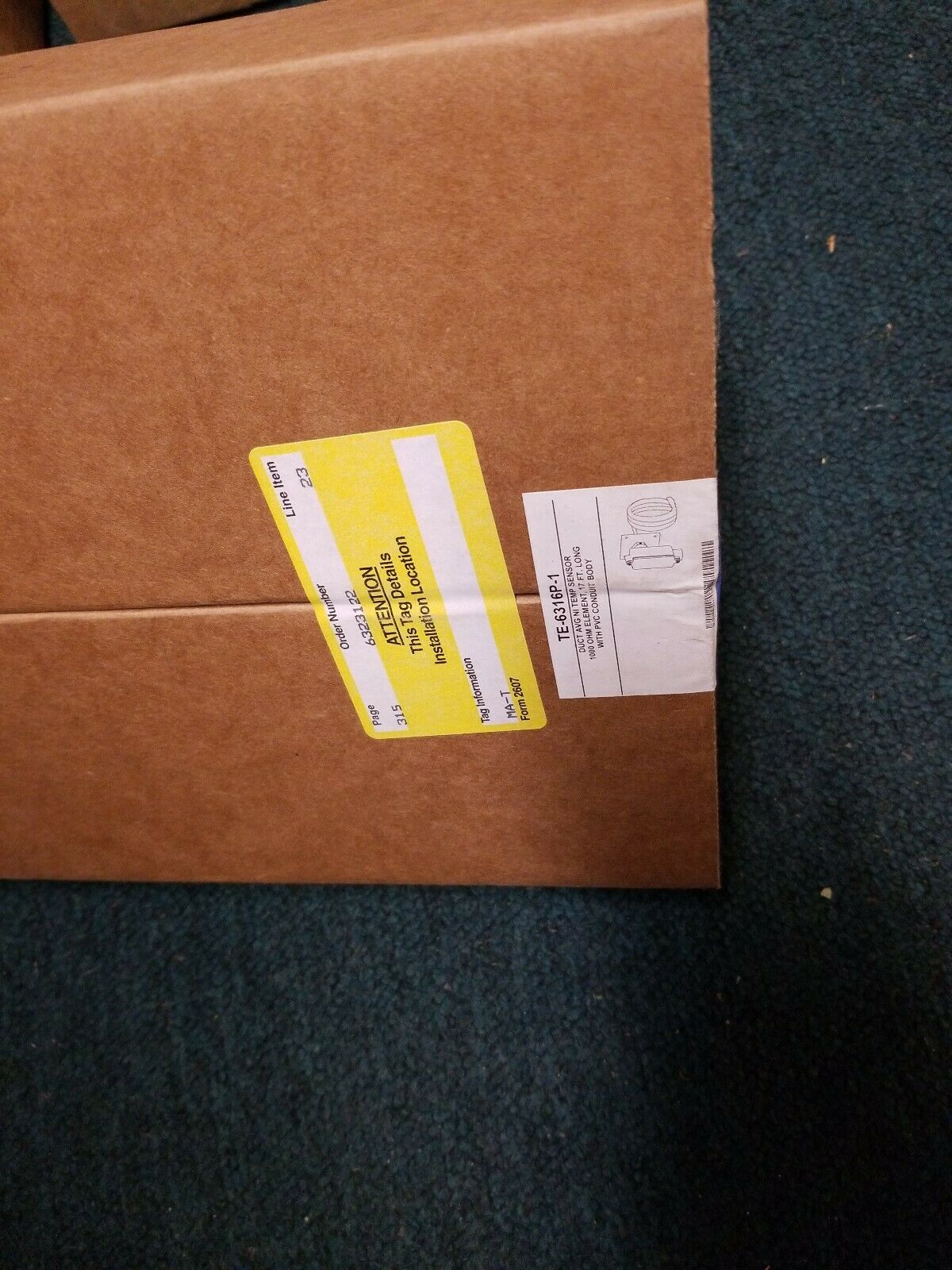

17' Nickle Temperature Sensing Element (1000 Ohm) TE-6316P-1

$ 31.67

- Description

- Size Guide

Description

The TE-6300 Temperature Sensor line provides economical solutions for a wide variety of temperature sensing needs, including wall-mount, outdoor-air, duct, strap-mount, well-insertion, duct-averaging, and Variable Air Volume (VAV) flange-mount duct-probe applications. The TE-6300 line offers both a metal and a plastic enclosure for the most popular models.To meet plenum rating where Underwriters Laboratories Inc.® UL 1995 rating is accepted, replace the existing thermoplastic cover with the TE-6001-13 Metal Cover. To meet International Mechanical Code standards, use all-metal components.

The TE-6300P Series Temperature Sensor is intended to provide an input to equipment under normal operating conditions. Where failure or malfunction of the sensor could lead to personal injury or property damage to the controlled equipment or other property, additional precautions must be designed into the control system. Incorporate and maintain other devices, such as supervisory or alarm systems or safety or limit controls, intended to warn of or protect against failure or malfunction of the sensor.

For 1k ohm nickel temperature sensors, wire resistance can cause approximately 1F° (0.56C°) of error for every 250 ft (76 m) run of 18 AWG wire, or every 100 ft (31 m) run of 22 AWG wire. For 1k ohm platinum temperature sensors, wire resistance can cause approximately 1F° (0.56C°) of error for every 150 ft (46 m) run of 18 AWG wire, or every 50 ft (15 m) run of 22 AWG wire. To minimize error due to field wiring, limit the total resistance of all nickel temperature sensor wiring to 3 ohms, and all 1k ohm platinum temperature sensor wiring to 2 ohms. To minimize wiring error in applications using 100 ohm platinum equivalent sensors, use the TQ-6000-1, 4 to 20 mA transmitter. Using a 4 wire (Kelvin) connection can also eliminate wiring error. The 2.2k and 10k ohm thermistor applications permit wiring to be relatively long before wire resistance adds significantly to total resistance measured at the controller. As a general rule, a 150 ft (46 m) two-wire 18 AWG run contributes 2 ohms of error, or less than 1F° (0.56C°) error over the sensor operating temperature range. Refer to the appropriate controller documentation for recommended sensor wiring. See Table 2 for an explanation of the lead wiring color convention